Find out more about how this label is awarded on the Blue Angel website

Search

Standorte PAKUFOL

Mit einem Klick bestens im Bilde. Informieren Sie sich über unseren Betriebsstandort und die jeweiligen Angebote sowie Kontaktmöglichkeiten.

Our mission: to promote sustainable plastic products

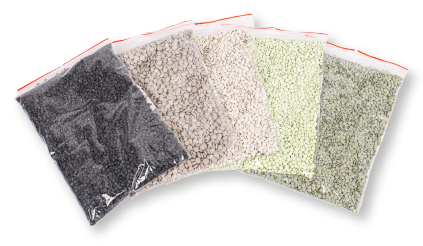

Ever since our company was founded more than 35 years ago, we have systematically focused on manufacturing sustainable plastic film products. Because this is what we believe in. Each and every plastic sack and refuse sack we produce is made purely from recycled material that our own recycling division has recovered from old plastic film. This means that we not only have optimum quality control over each individual stage of our business operations. It also makes our plastic products twice as sustainable. If we didn’t recover the old plastic film and recycle it into pellets, then it would end up at incineration plants and the raw material would be lost to us forever.

Producing sustainable plastic sacks – a detailed look at our closed-loop principle

The Blue Angel – a regular guest at our company. But no reason to relax

We are proud of the fact that we were one of the very first producers of plastic film to be awarded RAL’s Blue Angel label. This eco-label gives consumers the assurance they need and allows them to select products that are particularly environmentally friendly throughout the whole of their production and life cycle. Our plastic sacks have been permitted to use the Blue Angel label since 1991. And we have been facing the challenge of making our sustainable plastic products even better ever since. Why? Because the Blue Angel label has to be earned again and again. It is awarded when specific criteria have been met and these criteria are reviewed and revised by the UBA [Federal Environment Agency] every three to four years. But even if we didn’t have to meet these criteria, we wouldn’t be resting on our laurels. Being sustainable and making our products ever more environmentally friendly is in our company’s DNA.

Plastics are made from one of our planet’s most valuable and most scarce resources: crude oil. It is vital to make the very most of recycling to prevent this resource being further depleted.

On the way to being 100% net zero

Sustainability and climate action are two sides of the same coin and most certainly go hand in hand at our company as well. By using high quality recyclate instead of pellets made from virgin material, our production operations reduce carbon emissions by a considerable amount. In 2022, we decided to find out the exact amount and commissioned the prestigious Fraunhofer Institute to calculate our CO2 savings. The institute’s experts took a detailed look at the way we produce plastic film using recyclate and then compared it with plastic film production using virgin raw materials made from crude oil. They have certified that our operations cut carbon emissions by up to 60%. And that adds up to quite a lot considering that we produce over 1½ million sacks a day. Key factors here are the recycled raw material we use – which is considerably less CO2 intensive – and the fact that all our production operations are carried out at one single site. This means that none of our in-house processes – from producing the pellets to manufacturing the plastic film – generate transport-related emissions. All this certainly doesn’t mean that our efforts to reduce our carbon emissions have been exhausted though. We are working tirelessly to make our business completely net zero and are permanently sounding out ways to further reduce our emissions.

Sustainability as a service. Recycling your old plastic film

Does your company generate waste PE film? Then we would be more than happy to handle the recycling of this material – from A to Z, of course. This means that we draw up a concept to meet your precise requirements. One of the reasons why we are able to offer you a full range of services is because we are part of the REMONDIS Group. This enables us to cover the whole of the supply chain – from delivering the bins and containers for storing the materials, to collecting the materials, all the way through to processing them in our modern recycling facilities. You don’t need to do anything and can rest assured that your waste plastic film is being recycled in the most sustainable way possible.

Would you like to help conserve natural resources and curb climate change by having us recycle your old plastic film? Then why not get in touch now?!